- info@nuteckcouplings.com

- +91 20 27120103 / 27120104

Full Flexible Gear Couplings

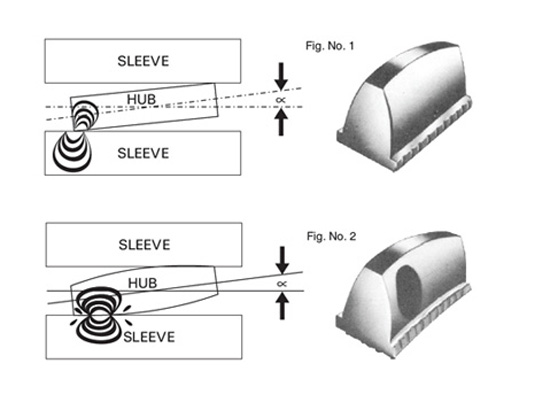

Under the misalignment condition of two shafts of the equipment, the teeth contact in case of straight cut hub will be as minimum as shown in the figure no. 1.

Under heavy loads the ends of the hub teeth will get damaged resulting in the excessive play between hub & sleeve. This leads to the reduction in life of coupling.

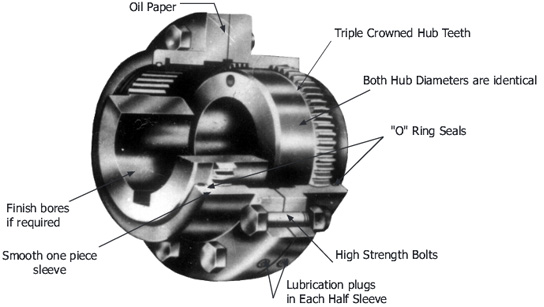

NU-TECK Triple Crowned Teeth

The triple crowned teeth hub is manufactured on a fully automatic hobbing machine with built-in crowning attachment. It is controlled by hydraulic & electronic systems. Under the misalignment condition of two shafts on the equipment, due to the curvature on teeth flank the contact area is much more. Thus, in turn, there is an increase in the life of the coupling.

Misalignment Details

In case of straight tooth gear coupling the maximum allowable angular misalignment (μ) is .1/2 deg. and in case of Nu-Teck Triple Crowned Tooth Gear Coupling the misalignment is 1.1/2 deg.

| Service Factor | Primer Mover | ||

| Driven Unit (Machinery) |

Electric Motor or Steam Turbine |

Gasoline or Diesel Engine 4 or mor cyl. |

Gasoline or Diesel Engine, more then 6 cyl. |

LIGHT :

|

1.0 | 1.5 | 2.0 |

MODERATE :

|

1.5 | 2.0 | 2.5 |

HEAVY :

|

2.0 | 2.5 | 3.0 |

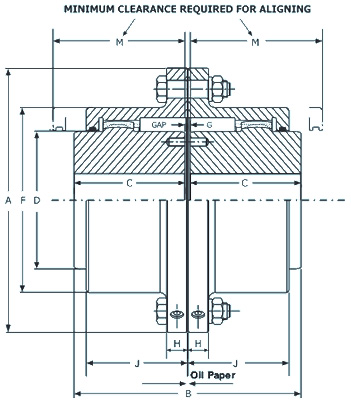

| NU-TECK G. C. NO. |

Load Capacity | Max. R.P.M. |

Bore Min. |

Bore Max. |

Dimension In MM | WR2 Kgm2 |

Wt. In Kg. |

|||||||||

| H. P. Capacity at 100 R.P.M. |

Max. Torque Kg. M. |

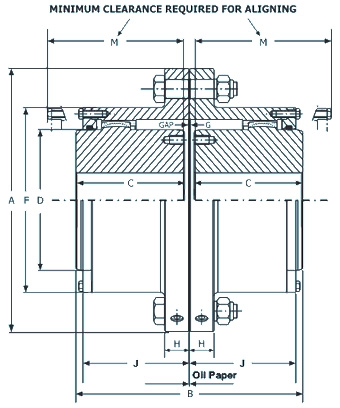

A | B | C | D | F | G | H | J | M | ||||||

| GC-100 | 7 | 50 | 8000 | 12 | 32 | 120 | 93 | 45 | 50 | 75 | 3 | 15 | 40 | 55 | 0.03 | 4.5 |

| GC-101 | 17 | 125 | 6300 | 20 | 45 | 170 | 115 | 55 | 65 | 110 | 5 | 17 | 49 | 65 | 0.14 | 11 |

| GC-102 | 42 | 300 | 5000 | 30 | 60 | 185 | 145 | 70 | 85 | 125 | 5 | 17 | 62 | 80 | 0.20 | 15 |

| GC-103 | 75 | 540 | 4000 | 40 | 75 | 220 | 175 | 85 | 105 | 150 | 5 | 20 | 78 | 105 | 0.48 | 25 |

| GC-104 | 135 | 985 | 3350 | 50 | 90 | 250 | 215 | 105 | 130 | 175 | 5 | 20 | 96 | 125 | 0.95 | 39 |

| GC-105 | 210 | 1505 | 2800 | 60 | 110 | 290 | 230 | 110 | 155 | 204 | 10 | 25 | 108 | 140 | 1.90 | 57 |

| GC-106 | 325 | 2330 | 2500 | 75 | 125 | 320 | 260 | 125 | 175 | 235 | 10 | 25 | 118 | 155 | 3.00 | 85 |

| GC-107 | 560 | 4000 | 2100 | 90 | 140 | 350 | 290 | 140 | 205 | 265 | 10 | 25 | 136 | 175 | 5.25 | 103 |

| GC-108 | 720 | 5140 | 1900 | 105 | 160 | 380 | 320 | 155 | 230 | 295 | 10 | 25 | 149 | 190 | 8.50 | 138 |

| GC-109 | 895 | 6400 | 1700 | 125 | 180 | 430 | 340 | 165 | 250 | 336 | 10 | 27 | 160 | 205 | 15.00 | 210 |

| GC-110 | 1290 | 9225 | 1400 | 140 | 220 | 490 | 370 | 180 | 310 | 396 | 10 | 27 | 175 | 220 | 30.50 | 277 |

| NU-TECK G. C. NO. |

Load Capacity | Max. R.P.M. |

Bore Min. |

Bore Max. |

Dimension In MM | WR2 Kgm2 |

Wt. In Kg. |

|||||||||

| H. P. Capacity at 100 R.P.M. |

Max. Torque Kg. M. |

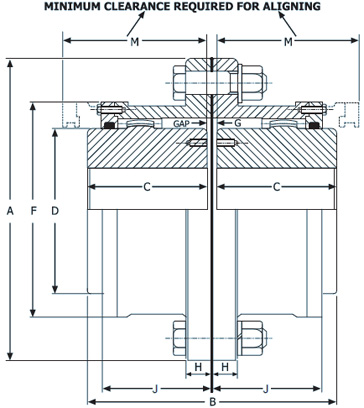

A | B | C | D | F | G | H | J | M | ||||||

| GC-111 | 1700 | 12220 | 1250 | 160 | 260 | 545 | 410 | 200 | 350 | 451 | 10 | 30 | 192 | 240 | 58 | 550 |

| GC-112 | 2250 | 16170 | 1120 | 180 | 300 | 590 | 490 | 240 | 405 | 496 | 10 | 30 | 231 | 280 | 88 | 710 |

| GC-113 | 3025 | 21660 | 1000 | 200 | 330 | 680 | 535 | 260 | 440 | 566 | 15 | 35 | 242 | 310 | 138 | 980 |

| GC-114 | 4300 | 30800 | 900 | 220 | 370 | 730 | 575 | 280 | 500 | 616 | 15 | 35 | 266 | 330 | 291 | 1320 |

| GC-115 | 5200 | 37230 | 800 | 250 | 410 | 780 | 655 | 320 | 550 | 666 | 15 | 35 | 305 | 370 | 353 | 1700 |

| GC-115 M | 7480 | 53570 | 750 | 300 | 420 | 825 | 690 | 335 | 558 | 690 | 20 | 45 | 320 | 400 | 500 | 2000 |

| GC-116 | 8380 | 60000 | 710 | 300 | 455 | 900 | 720 | 350 | 630 | 775 | 20 | 45 | 330 | 420 | 691 | 2550 |

| GC-116 M | 10145 | 72000 | 670 | 330 | 480 | 950 | 770 | 375 | 680 | 810 | 20 | 45 | 340 | 460 | 965 | 3100 |

| GC-117 | 11917 | 85350 | 630 | 375 | 520 | 1000 | 820 | 400 | 720 | 855 | 20 | 45 | 386 | 460 | 1235 | 3620 |

| GC-118 | 15778 | 113000 | 560 | 450 | 610 | 1100 | 920 | 450 | 810 | 950 | 20 | 55 | 430 | 510 | 1965 | 4860 |